Striving to Become the Global Brand Aderans

As an unparalleled global total hair solution provider, the Aderans Group aims to bring smiles to the faces of people across the world so they can fulfill their dreams and live full, happy lives.

The Aderans Group in Numbers

-

Salons and

Shops across the

WorldApprox.0locations

-

Total Number of

Employees0people

-

Net Sales

CompositionDomestic0:0Overseas

-

Consolidated Net

SalesApprox.0billion

(fiscal 2024)

-

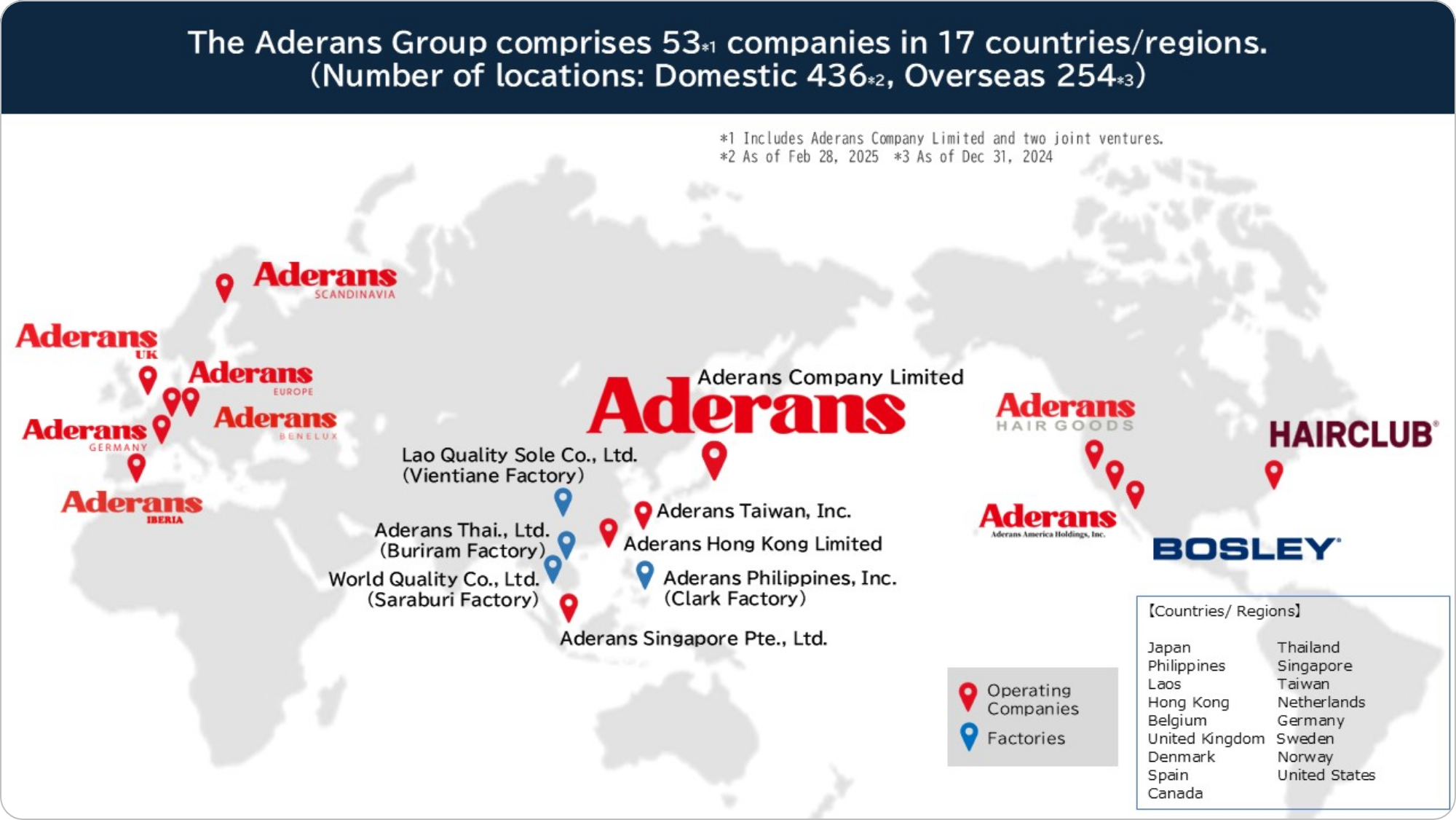

Our Global Network

0countries and regions

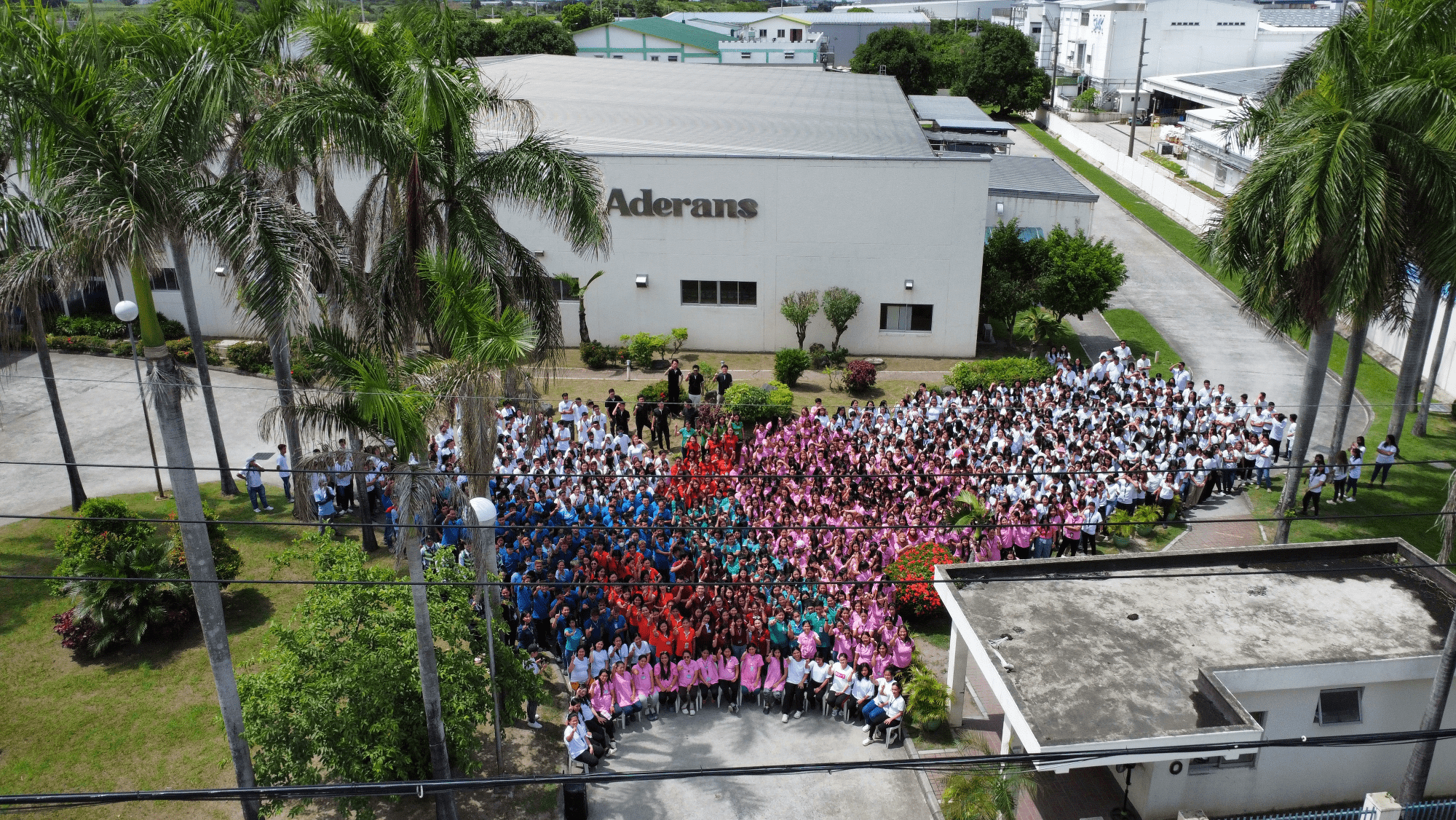

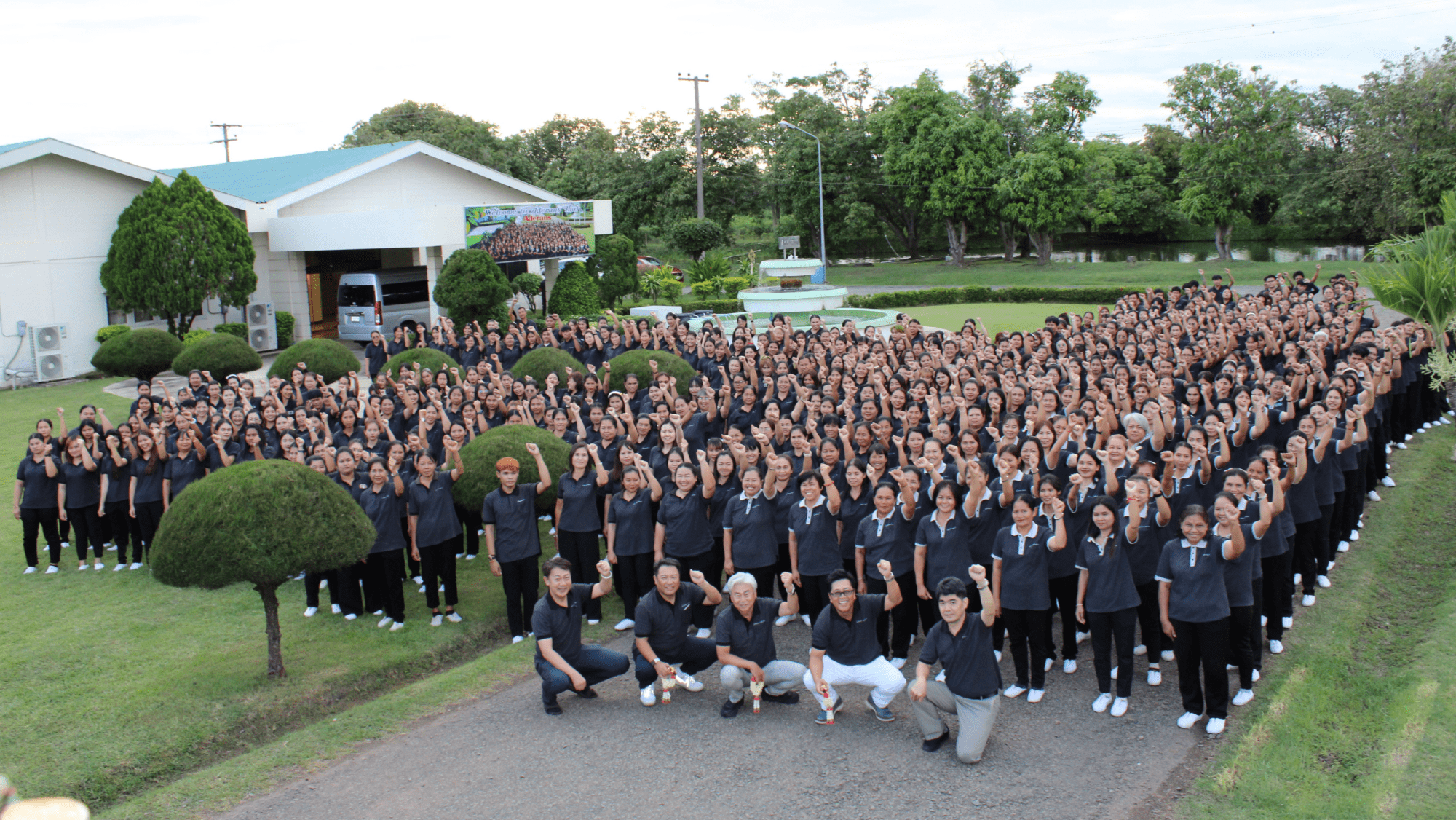

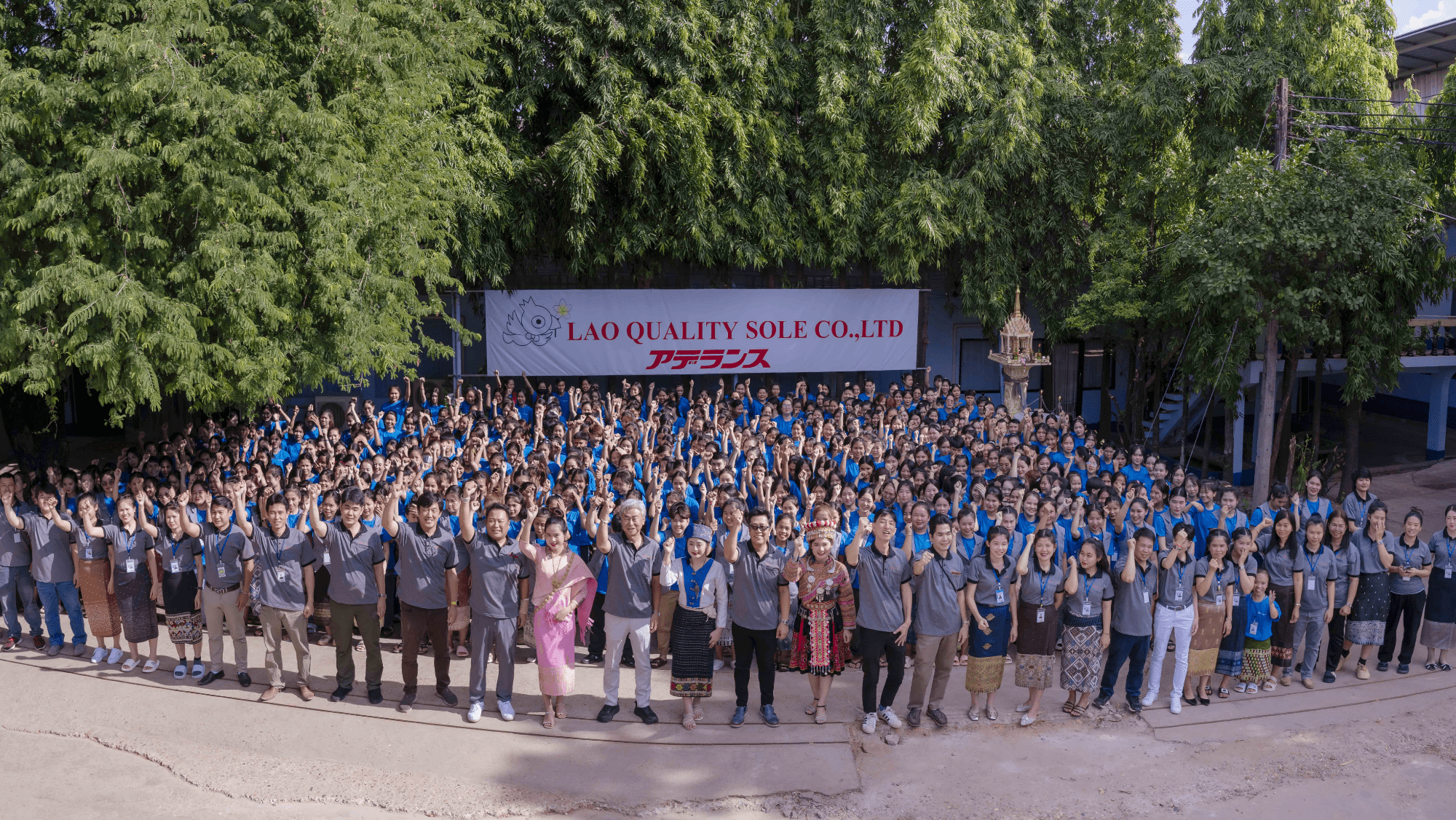

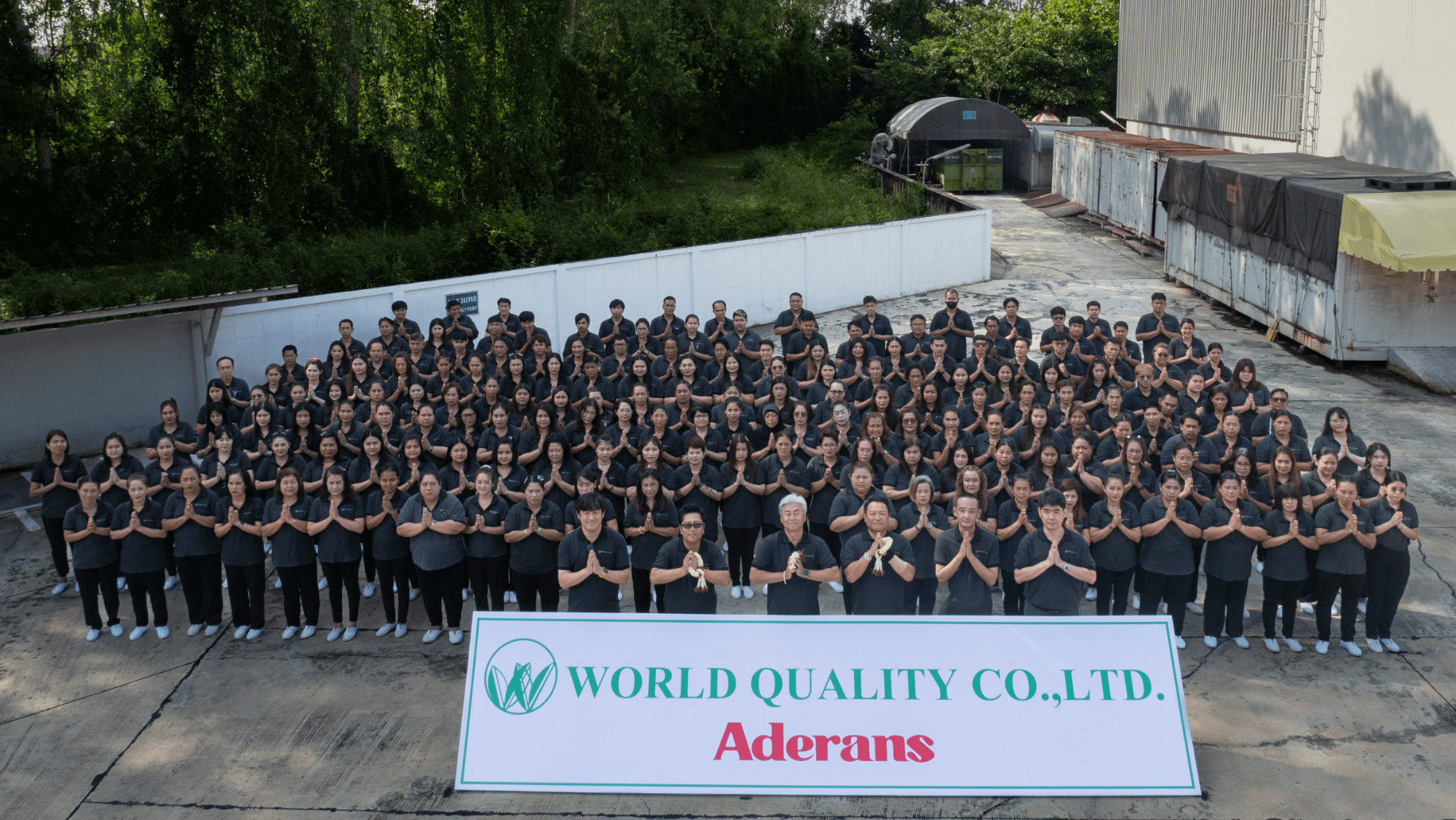

Our Global Presence

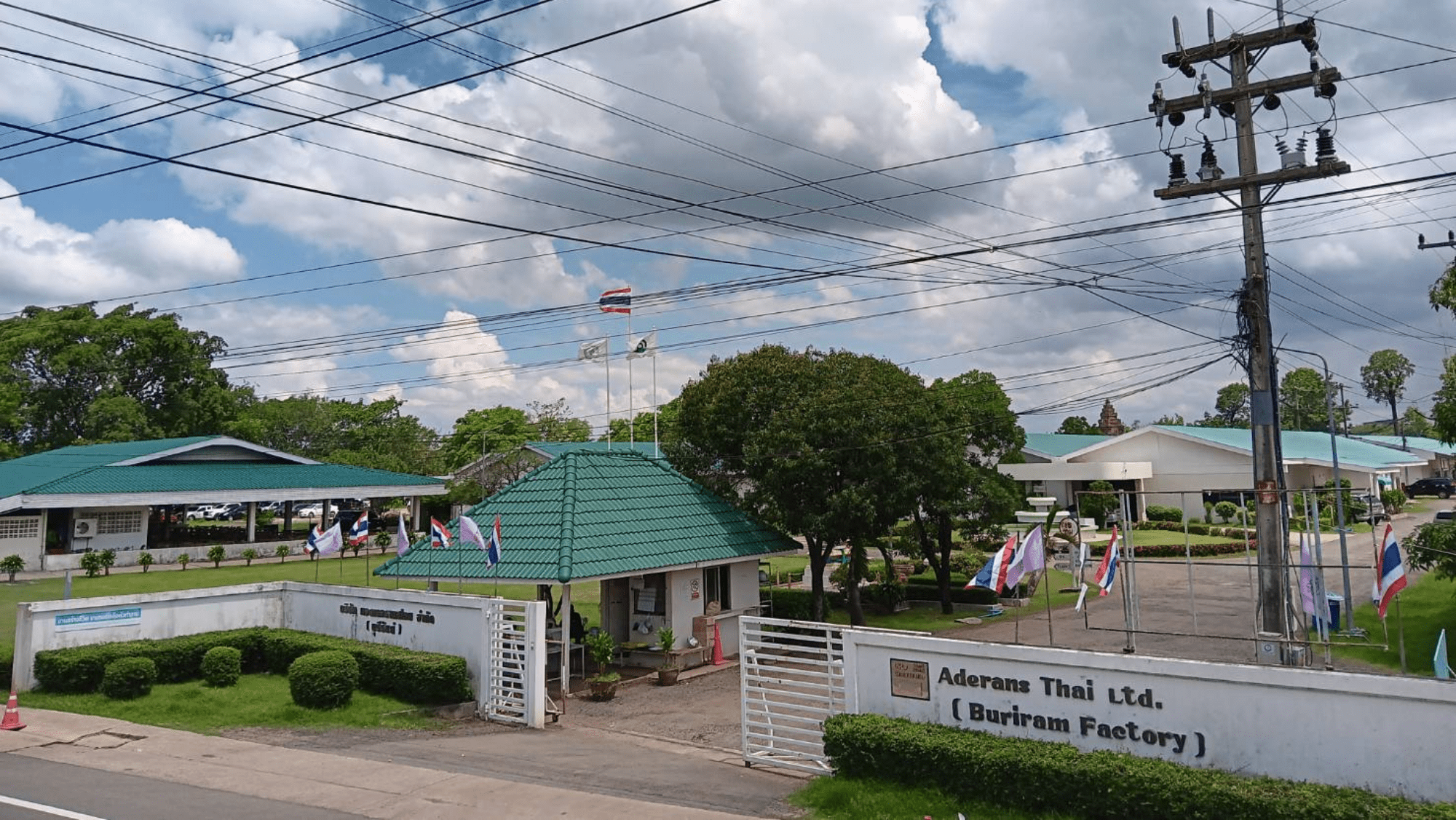

Integrated Production and Marketing Structure

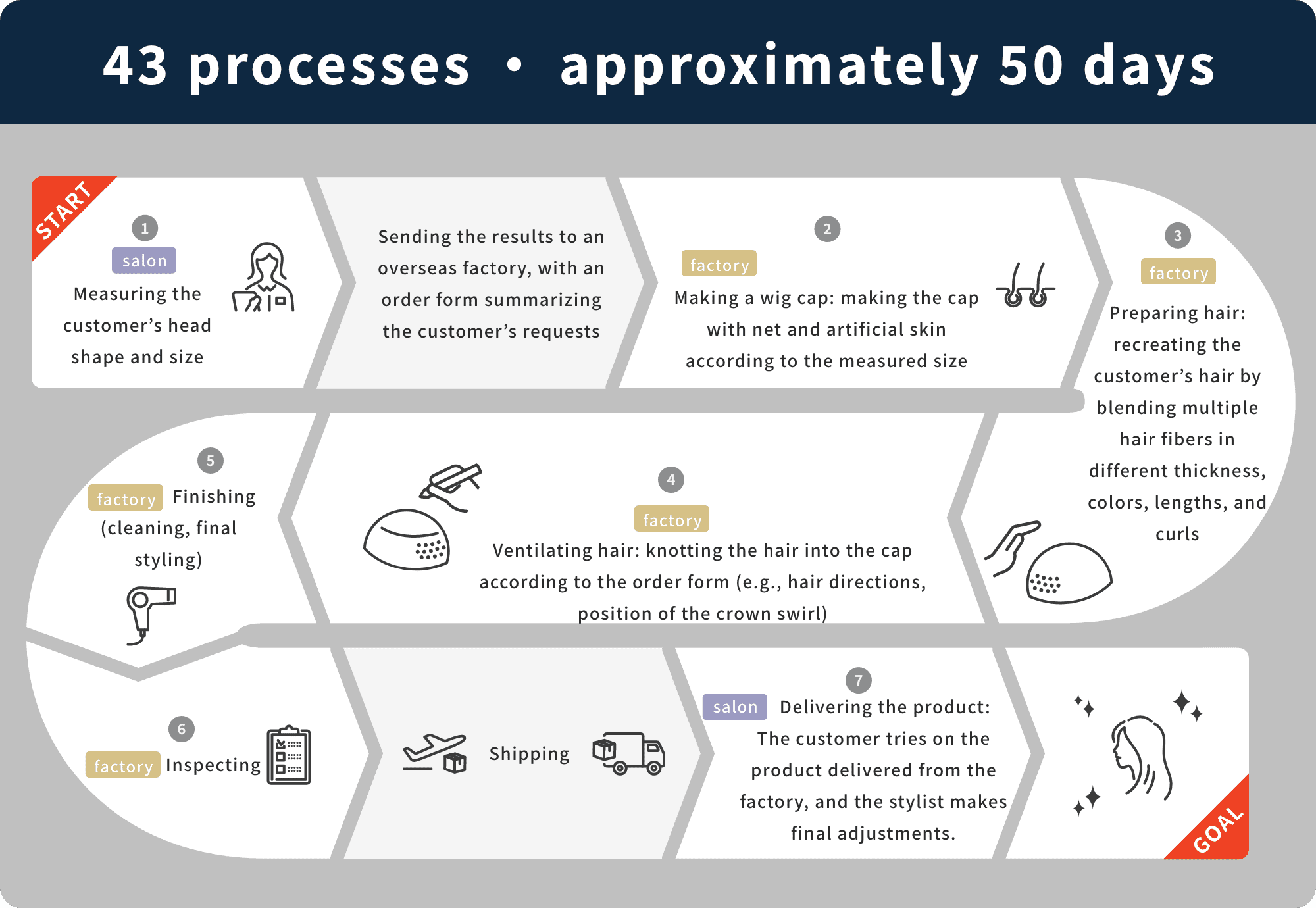

How a custom-made wig is made

Aderans' custom-made wigs are delicately constructed, tailored to each customer, by our experienced technicians. Let us introduce how the wig is made, from product order to delivery.

「How a custom-made wig is made」

To Deliver Product Excellence

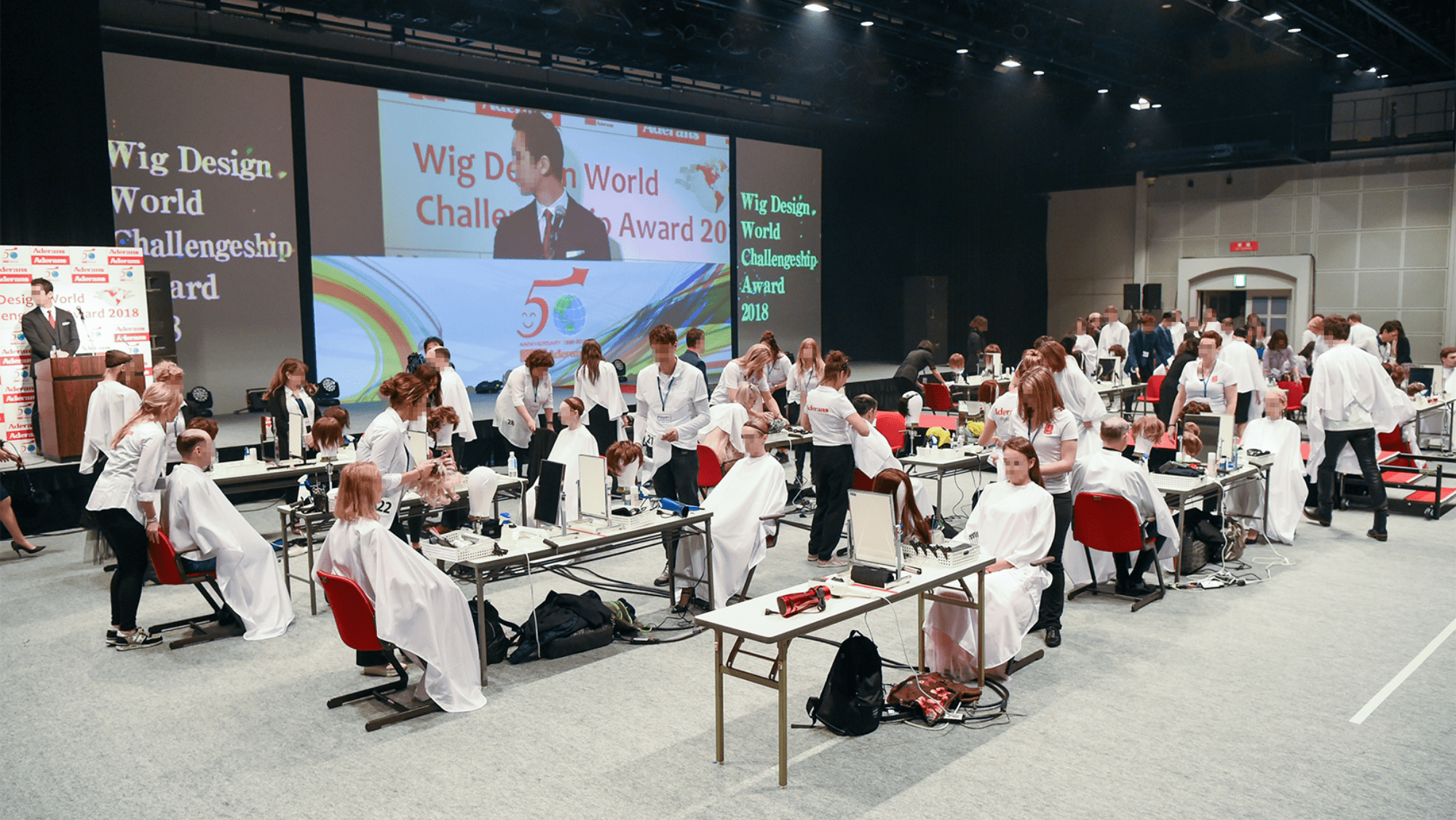

Skill development

The Aderans Group employs numerous licensed barbers and beauticians who are dedicated to enhance their technical skills.

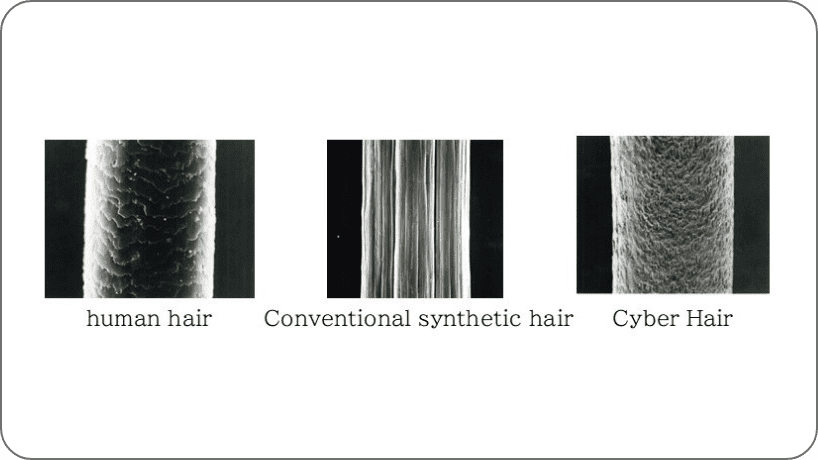

Aiming for artificial hair that goes beyond human hair

Aderans is the only company in Japan to cover the entire process of artificial hair, from its development to in-house production. Foreseeing the depletion of human hair, which is often used for custom-made wigs, we started research on artificial hair in 1983 to ensure stable wig supply.

We have also commissioned a company in Tsubame City, Niigata, to make our original scissors exclusively for artificial hair. These dedicated efforts have led to our technical excellence. Please click here for more information.

-

Cyberhair (1991)

Recreating the uneven texture just like the cuticle of human hair -

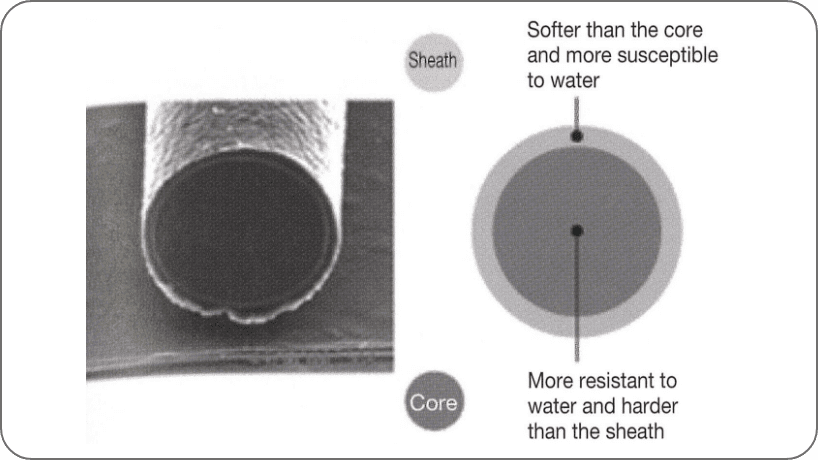

Vital Hair (2006)

Recreating the texture that can change with rain, water, and humidity like natural hair, with a dual sheath-and-core structure -

CYBER X (2022)

Recreating the shine just like human hair by finishing with a sea-island structure composed of polyamide and polyester